KLJF Screw-type Dewatering Device

1. Operational Principle

Materials are sent to the dewatering device through the pump or other methods. The extrusion screw installed on the sieve net makes the dehydrating material liquid pass to the dewatering device within 30 RPM. The liquid inside will be filtered by sieve net, and the solid materials which are formed in the machine mouth will be separated by extrusion.

2. Structure Features and Applications

The dewatering device body uses carbon steel or stainless steel material; the extrusion screw and sieve net are also made of stainless steel. The extrusion screw is special reinforcement by wing leaf to prevent abrasion; sieve net could choose meshes with different gaps, such as 0.5mm, 0.75mm, 1.0mm. The head of machine is dry and humidity is adjusted according to the different requirements of solid materials. KLJF Screw-type Dewatering Device is the hanging pipe structure, and its axle seat components directly connect with speed reducer, relay the guide rod to fixed end and the screw propeller connects with axle seat components through keyway. Mesh sieve is pushed forward through the guide groove and the materials enhance the feeding effect through vibrator. This equipment with its innovative structure principle goes through a stable and reliable operation, high efficiency, convenient operation and maintenance and has less vulnerable parts. It can be used for solid waste removal (waste residue, sludge) which has higher moisture content for further dehydration.

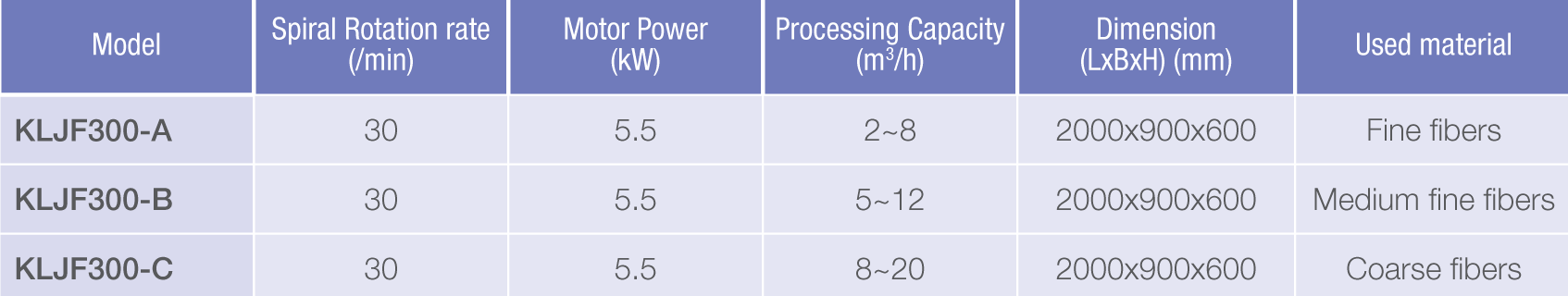

3. Main Technical Parameters

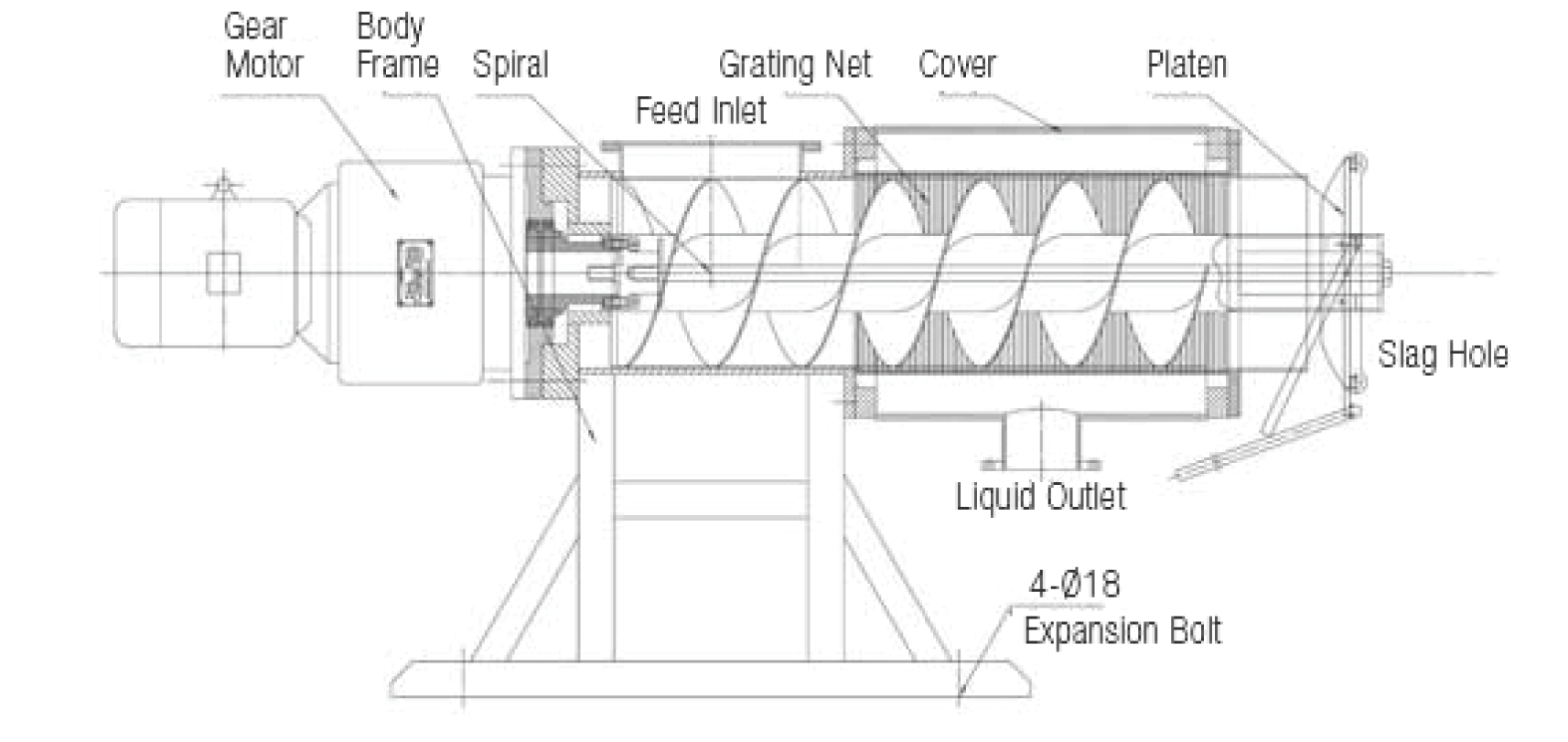

4. Equipment Outline and Schematic Diagram